I. What are the hidden dangers of using brass for busbars?

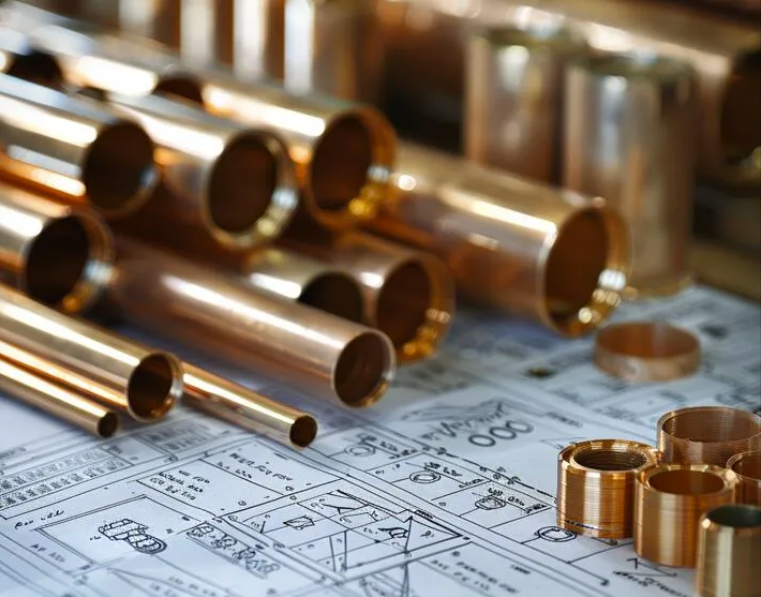

1. Electrochemical corrosion: Brass is mainly composed of copper and zinc (there are too many types of brass and the components are also complex.

The attached figure is as follows for reference). When brass is connected to pure copper or aluminum wires, it may form a micro-battery effect in a humid or corrosive gas environment,

leading to electrochemical corrosion, resulting in increased contact resistance, which may cause overheating, insulation damage,

reduced device life, and even fire and other safety accidents in the long term.

2. Difference in mechanical strength: Although brass has a higher hardness and is suitable for preventing stretching and bending,

it is not an advantage in scenarios that require good elasticity or tighter connections.

For example, when we talked about the coating problem in the copper busbar series, the flexibility of the connection part is an important point. If the flexibility is poor,

the overlap effect is poor, causing a high temperature rise; brass has higher mechanical strength and hardness than copper,

which affects the overlap effect and directly affects the efficient transmission of current, especially in high current applications, which is likely to cause local overheating.

3. Difference in conductivity: Brass has a slightly higher resistivity than copper, which generates more heat when current passes through it.

For applications that require low resistance and high efficiency in power transmission,

copper is a better choice because it provides a lower resistance path, reducing energy loss and heat generation.

4. Different thermal expansion coefficients: Brass has a different thermal expansion coefficient from copper or aluminum.

Due to the addition of zinc, brass has a higher thermal expansion coefficient than copper, depending on the content of the specific element.

This may cause the connection to loosen when the temperature changes, especially for large materials such as copper busbars.

The thermal expansion and contraction effect is more obvious, thus affecting the stability and safety of the electrical connection.

II. Why are the terminal blocks made of brass? Does it meet the standard?

Let's look at the standard first: "GB/T-14315-2008 Crimp-type copper and aluminum terminal blocks and connecting tubes for power cable conductors" requires:

It can be seen that the national standard has relatively loose requirements for terminal blocks.

Since there are national standards, why do some sites still require brass terminal blocks? Let's compare the advantages and disadvantages of brass and copper:

1. Copper (pure copper):

1) Excellent electrical and thermal conductivity, suitable for applications requiring efficient power transmission, ensuring rapid current flow and reducing heat generation.

2) Good ductility and plasticity, easy to process into various shapes, convenient for installation on wires and cables of different sizes.

3) Copper has relatively low mechanical strength and average wear resistance, and is not suitable for high mechanical stress or use in harsh environments.

4) The cost of brass is usually lower than that of copper, so using brass to make wire noses can reduce production costs while ensuring certain electrical conductivity.

2. Brass:

1) Made of copper and zinc alloy, it has good mechanical strength and wear resistance,

suitable for occasions requiring high mechanical stress, such as outdoor installation or industrial facilities.

2) Better corrosion resistance than copper, can remain stable in a variety of environments.

3) Although the electrical and thermal conductivity are not as good as copper, it is sufficient for non-extreme power transmission. And the cross-section can be made larger.

4) Brass has high hardness and wear resistance. It is more stable during connection and disassembly, which is conducive to the temperature rise of the lap joint.

In summary, we cannot only follow the national standard. If the application has extremely high requirements for electrical conductivity and thermal conductivity,

and environmental factors allow, copper is a better choice.

On the contrary, if better mechanical strength, wear resistance and corrosion resistance are required, or it is used in an environment where physical damage may occur,

brass is more suitable, but the quality of brass must be controlled. In order to reduce costs, some manufacturers use brass and even copper with more impurities,such as excessive zinc content, which leads to a significant reduction in the electrical conductivity, tensile strength and bending resistance of brass and copper,

affecting the quality of the terminal block.

Chat Online